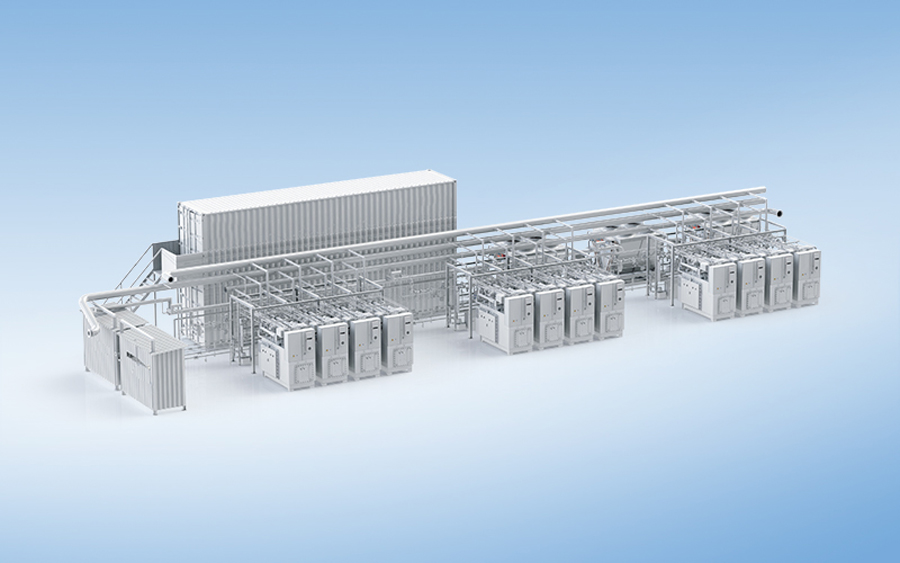

HIGH TEMPERATURE SOLID OXIDE ELECTROLYZER

Our (SOEC) high temperature solid oxide electrolyzer is a kind of equipment that uses industrial waste heat to process water vapor into green hydrogen with the highest conversion efficiency, and does not produce any pollution and greenhouse gases. The equipment adopts modular system design, which can operate at a high temperature of 850 °C to generate750 Nm³/h hydrogen with a power consumption of 3.6 kWh/Nm³. It is very suitable for steel mills, refineries and chemical industries as a low energy consumption and high efficiency hydrogen production solution.

225 kW Large High Temperature Electrolytic Module

SYSTEM FEATURES

1. Utilization of industrial off-heat as steam reduces electricity demand;

2. Market-leading efficiency (84 % LHV to AC) yields lowest hydrogen costs;

3. Certified electrolyzers with proven long-term operation;

4. Modular design simplifies scaling to any desired electrolysis capacity;

5. With sustainable application characteristics, turning industrial waste heat into treasure.

PARAMETER

| Hydrogen production | |

|---|---|

| Net production rate | 750Nm³/h |

| Production capacity dynamic range | 5 % ... 100 % |

| Hot idle ramp time | < 10 min |

| Delivery pressure | 0 bar (g) |

| Hydrogen purity | max. 99,99 % |

| Power input and electrical efficiency | |

| System power rating (AC) | 2,680 kW |

| Specific power consumption at stack level (DC) | 3.3 kWh/Nm³ |

| Specific power consumption at system level (AC) | 3.6 kWh/Nm³ |

| System electrical efficiency | 84 % |

| Steam input | |

| Consumption | 860 kg/h |

| Temperature | 150 ℃ ... 200 ℃ |

| Pressure | 3.5 bar (g) ... 5.5 bar (g) |

| Other specs | |

| Footprint | ~ 300 m² |

| Ambient temperature | -20 ℃ ... 40 ℃ |

APPLICATION

1. STEEL

Direct reduction of iron, blast furnace injection, protective atmosphere, etc.

2. REFINERIES

Desulphurization, hydrocracking, hydrogenation, etc.

3. CHEMICALS

Ammonia production, hydrogenation, isotope separation, etc.